About Cothrun Manufacturing

We are in the process of moving our domain and website to Squarespace! Please be patient with us while we are migrating!

Cothrun Manufacturing started in 2019 with a broad knowledge base and a long history of manufacturing technologies. With 20 years of machine shop experience, the owner has worked on various projects including aerospace machining, medical molds and tooling used in the production of angioplasty catheters, firearm accessory design and production, tool and die design and manufacturing, and 11 years or teaching manufacturing engineering at the local university.

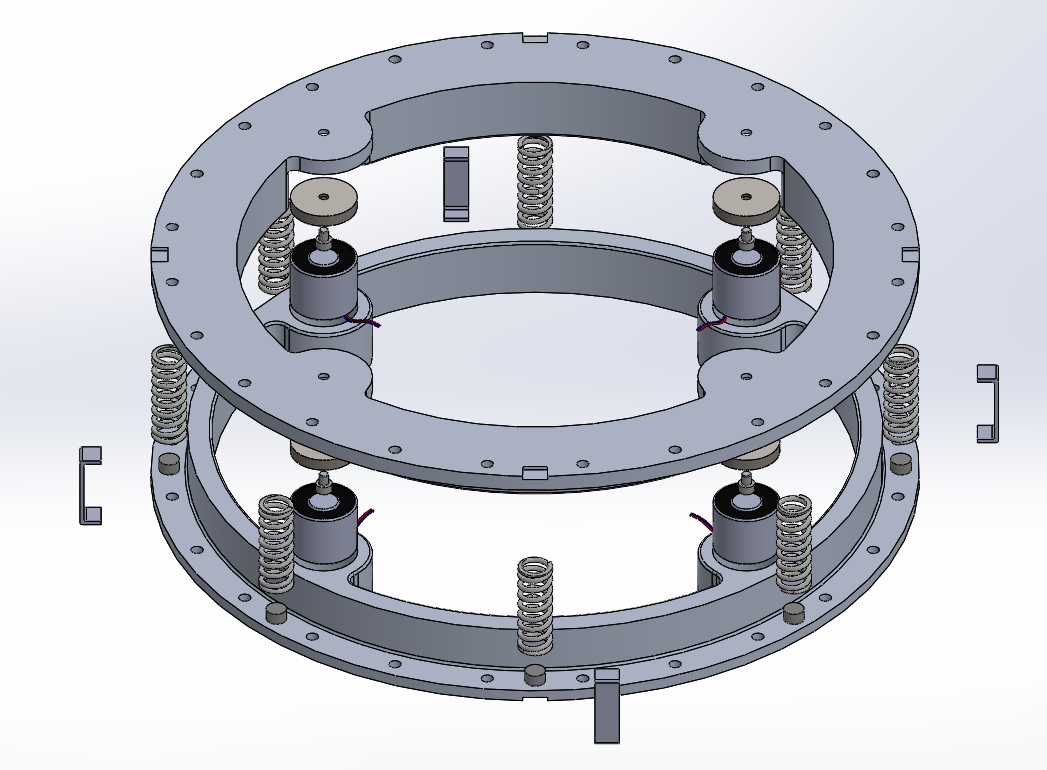

Cothrun Manufacturing holds a deep passion for problem solving, creating new and unique solutions to everyday problems, and ways to streamline existing manufacturing processes. Whether in our own shop or in yours! We have a long history of helping and participation in our local university’s mechanical engineering program senior capstone projects including:

Rocketry Team

Baja Racing Team

Hyper Milage and Human Powered Vehicle Team

Wind Turbine Team

We have also been working on a long list of product lines that will be for sale on our store front (coming soon).

Including gardening and greenhouse tools and equipment

Firearm accessories (not individual firearms)

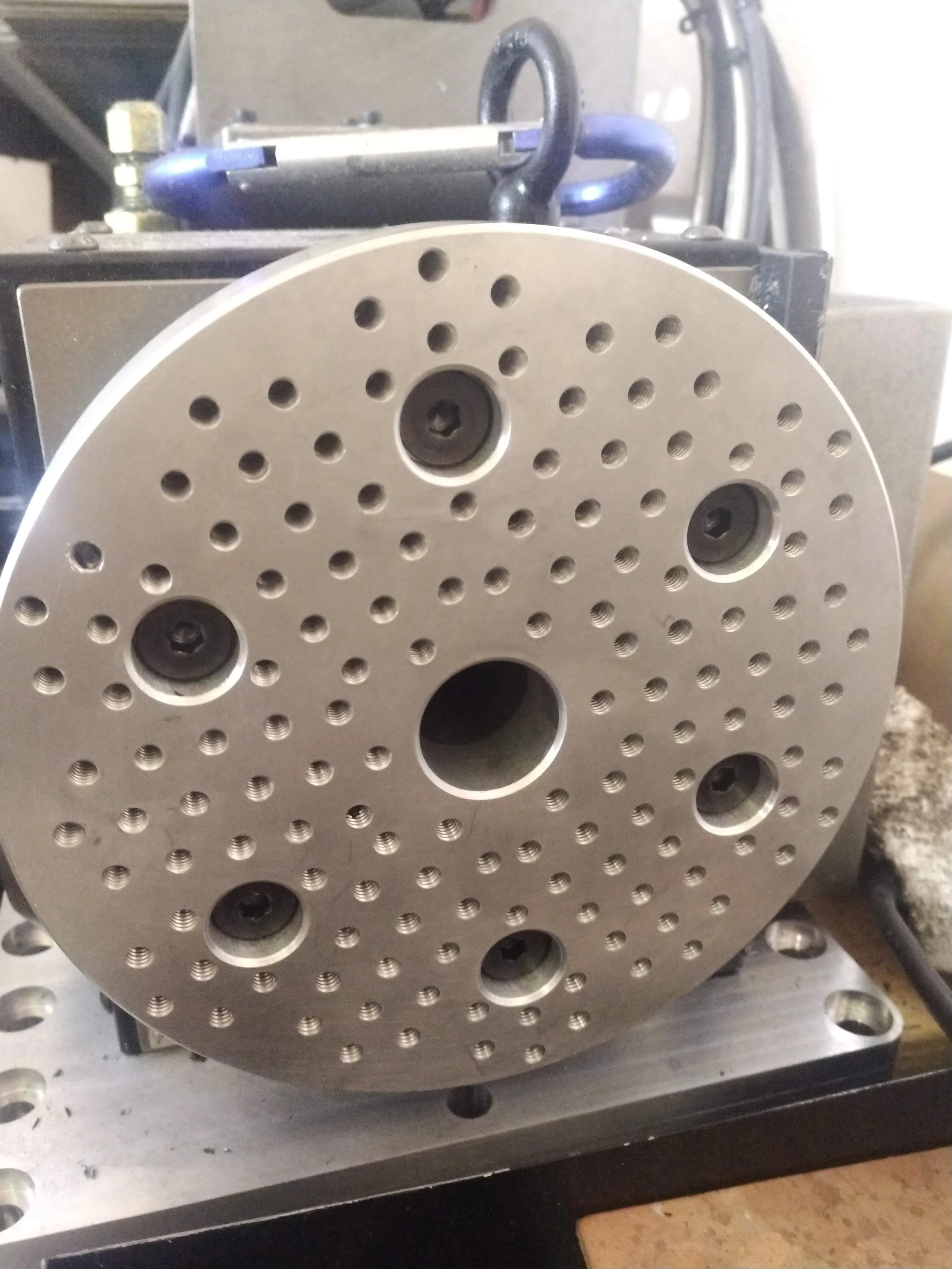

Machine shop fixturing and tools

Photography equipment and tripod adapters